During plastic manufacturing—especially in high-strain processes like injection moulding—internal or residual stresses are inevitably generated within the material. These stresses arise as polymer chains become highly aligned under rapid deformation, a condition common in fast-paced production environments. While not always visible, these internal tensions can significantly impair product performance, resulting in weakened impact strength, reduced chemical and wear resistance, environmental stress cracking, and other functional degradations. They may also manifest as physical deformations or optical issues, such as birefringence.

To counteract these effects, manufacturers often employ a thermal treatment known as annealing. This process involves gently heating the plastic to a temperature below its glass transition or softening point, followed by a gradual cooling phase. The goal is to allow the polymer chains to relax and reorient slightly, thereby relieving internal stress without compromising the shape or dimensions of the part. Annealing is a reliable method for enhancing product stability, dimensional accuracy, and long-term durability.

Annealing Process for Plastics:

The annealing process for plastic parts typically involves the following four stages:

Placement – The plastic part is placed inside a temperature-controlled annealing oven.

Heating – The part is gradually heated to the annealing temperature, typically at a controlled rate of less than 1 °C/min.

Soaking – The part is held at the target temperature for a specified duration, depending on the polymer type and part thickness; this period can range from several hours to a few days.

Cooling – The part is then cooled down to room temperature at a slow rate, usually less than 0.5 °C/min.

There are two main types of annealing processes for plastics:

Batch Annealing – The most commonly used method, where plastic parts are arranged on shelves or racks inside the oven.

Continuous Annealing – Typically used for high-volume production or specific processing needs.

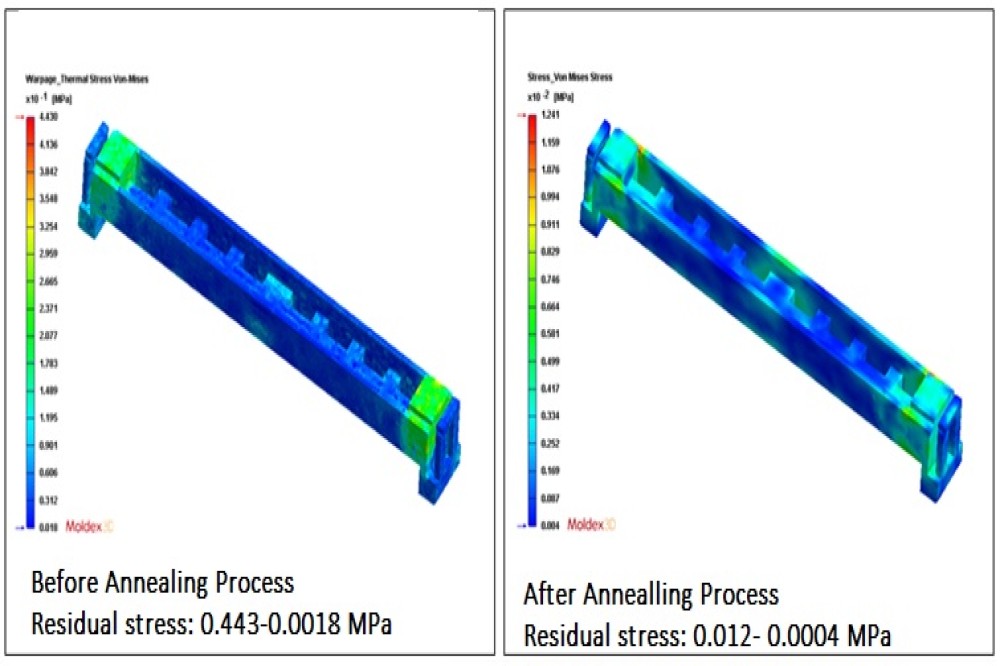

Moldex3D Stress offers an annealing simulation tool that helps users predict and analyze stress relaxation and deformation during the annealing process (see fig below)

Advanced Stress and Warpage Prediction with Moldex3D:

For manufacturers focused on enhancing product quality, Moldex3D Stress offers advanced tools to simulate warpage and internal stress behaviour influenced by the annealing process. It also allows precise tracking of dimensional changes in components throughout annealing, as depicted in Fig. .

Complementing this, Moldex3D Material Lab delivers comprehensive viscoelastic property characterisation, enabling accurate material input for simulation. Users have the flexibility to apply either:

Linear elastic models for rapid stress evaluations, or

Viscoelastic models for higher fidelity results.

Together, these capabilities empower engineers to predict post-processing deformation and improve part stability—leading to more consistent, high-quality outcomes.

Control geometry precision through annealing stress analysis and warpage analysis.

Linear elasticity theory and viscoelastic theory in stress analysis is available in options for annealing process