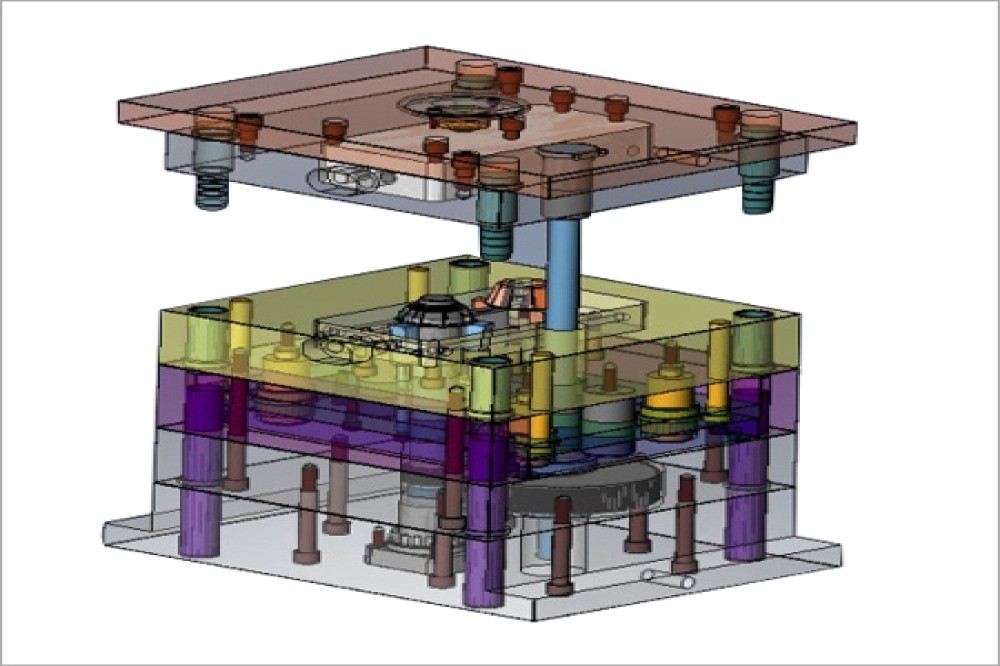

In injection molding, the cooling system is one of the most critical yet often underestimated factors affecting product quality and production cost. Cooling typically consumes up to 70% of the molding cycle time. An inefficient design can lead to longer cycles, higher energy costs, and quality issues like warpage, sink marks, and uneven shrinkage.

At Rheologist Gaze & Solutions, we utilize Moldex3D Cooling Simulation to help mold designers and manufacturers achieve efficient cooling performance, uniform temperature control, and shorter cycle times—all before the mold is even built.

The cooling system’s purpose is to remove heat from the molten plastic efficiently and uniformly. Poorly designed cooling channels can cause:

Uneven part shrinkage

Increased cycle time

Surface blemishes or dimensional instability

Frequent mold rework

As product geometries grow more complex, relying solely on experience or empirical design methods is no longer enough. Simulation-based cooling design using Moldex3D offers a precise and predictive way to address these issues.

Moldex3D provides a 3D, physics-based analysis of heat transfer, coolant flow, and temperature distribution across both the mold and the plastic part.

Key capabilities include:

Conventional and Conformal Cooling Evaluation

Simulate straight-drilled or conformal channels (ideal for additive-manufactured molds) and compare their thermal efficiency.

Cooling Performance Visualization

Get 3D temperature maps to identify hot spots, cold zones, and heat accumulation areas.

Design Parameter Optimization

Adjust channel layout, diameter, flow rate, and coolant type to balance cooling efficiency and manufacturability.

Integration with Filling and Warpage Simulation

Combine cooling simulation with filling and packing analyses to predict final part deformation with high accuracy.

DOE and Automatic Optimization

Moldex3D’s DOE tool systematically explores multiple design variables and process settings to deliver the best combination of cooling performance and cycle time.

| Feature | Traditional Design Approach | With Moldex3D Simulation |

|---|---|---|

| Cycle Time Estimation | Based on experience | Precisely predicted and minimized |

| Cooling Uniformity | Hard to verify | Clearly visualized via 3D maps |

| Hot Spot Detection | Found post-production | Detected early in virtual model |

| Process Tuning | Manual trials | Automated DOE optimization |

| Mold Modification | High cost | Reduced via virtual validation |

An automotive housing component was facing warpage and long cooling time issues. Using Moldex3D Cooling Analysis, our engineering team at Rheologist Gaze & Solutions redesigned the cooling layout and applied conformal channels to improve heat extraction efficiency.

Results achieved:

30% reduction in cycle time

Improved part dimensional stability

Uniform temperature across cavities

Reduced residual stress and warpage

This simulation-driven redesign led to faster production, fewer mold trials, and a more reliable manufacturing process.

As an authorized reseller and certified service partner of Moldex3D, Rheologist Gaze & Solutions provides not only simulation software but also expert consultancy in:

Plastic product and mold design

Moldex3D simulation setup and analysis

DOE-driven cooling system optimization

Fixture and tool design integration

We combine engineering expertise, simulation intelligence, and hands-on industry experience to help manufacturers achieve:

Lower operational costs

Consistent product quality

Sustainable and energy-efficient manufacturing

Efficient cooling system design is the foundation of high-performance injection molding. With Moldex3D Cooling Simulation, engineers can visualize heat transfer behavior, optimize cooling efficiency, and ensure uniform part quality—before cutting any steel.

At Rheologist Gaze & Solutions, we empower industries to innovate, create, and excel using the power of simulation-driven cooling design.