Compression Molding

Compression molding enables the production of complex composite components at fast rate, Moldex3D supports many discontinuous FRP materials that frequently used in compression molding including thermoplastics material GMT, LFT-G and LFT-D. Thermoset type is also supported by Moldex3D, such as SMC and BMC materials.

Challenge

- Proper amount of material

- Predict the required force to ensure that shot attaining the proper shape

- Provide appropriate compression parameters to assure quality compression effects

- Design the mold for heating or cooling after the material has been compressed into the mold

- Detect potential flash issue

- Achieve product consistency control

What Can Moldex3D Do?

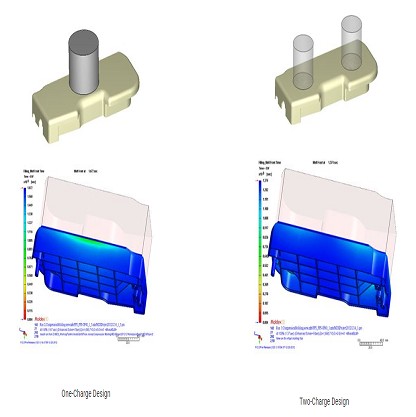

- Simulate the filling process with single or multiple charge design

- Visualize pressure distribution, volume shrinkage, residual stress, fiber orientation distribution, etc.

- Predict potential molding defects, such as bleeding or flashing

- Optimize process conditions, such as compression speed, force, or mold temperature

- Support fiber orientation analyses

- Support parallel processing to speed up the simulation

- Support the molding simulation of single or multiple charge design